Serving the music community since 1991

HOME | WANTED | REPAIR SERVICES | GALLERY| INSTRUMENT SALES | EMAIL

Oberloh Woodwind and Brass Works offers a comprehensive level of service where brass instrument piston and rotary valve repair and/or rebuilding is concerned. Our tooling and know-how is not limited to any particular size or group of instruments. Valve rebuilding services offered include most all piston valve designs, from the smallest of bore trumpets and cornets to J and K series Conn "short stroke" tubas and sousaphones. Services also apply to almost all makes and models produced in the past 180 years and includes valves made of brass, nickel silver, other assorted copper alloys and stainless steel.

About Our Services

With over thirty-five years of experience in the band instrument repair industry, Daniel Oberloh's expertise is supplemented with a background that includes machining and electroplating (both decorative and structural copper and nickel). His depth of knowledge and experience offers unparalleled opportunities for valve repairs that few instrument repair shops can offer. All of our valve repair services are performed here in our Seattle facilities. Capabilities also include machining custom tooling, arbors and electroplating fixtures as needed. Our valve repair services range from the simplest and most basic to remanufacturing complete piston assemblies, caps, stems and buttons.

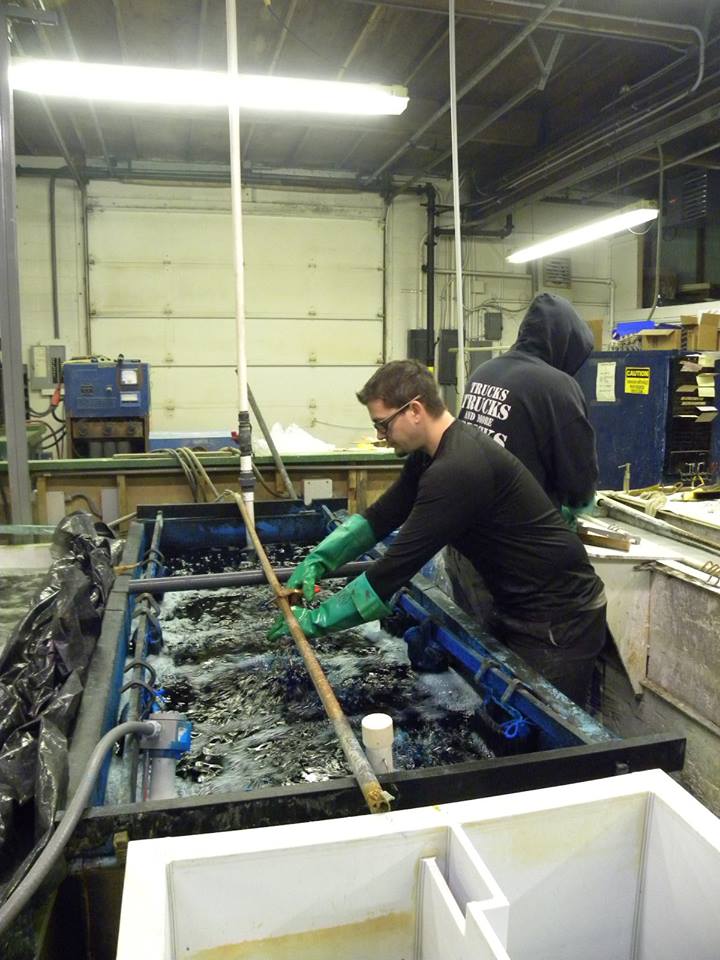

Plating

Our structural plating services are performed by Mike Wheeler at Electrofinishing in Kent Washington, under the personal supervision and oversight of Daniel Oberloh.

Precision Honing and Sizing

The critical matter of piston and valve cylinder honing and sizing is performed personally by Daniel Oberloh, with the highest standards of precision workmanship on only the very best equipment. All of our piston-valve and cylinder honing is performed with machines, tooling and supplies, provided by Sunnen Products Corp.

In addition to our private customers, we gladly provide support services to our repair industry colleagues and commercial music companies throughout North America, Europe, the South Pacific, New Zealand and Australia. If your shop is interested in our services, please feel free to contact us for detais.

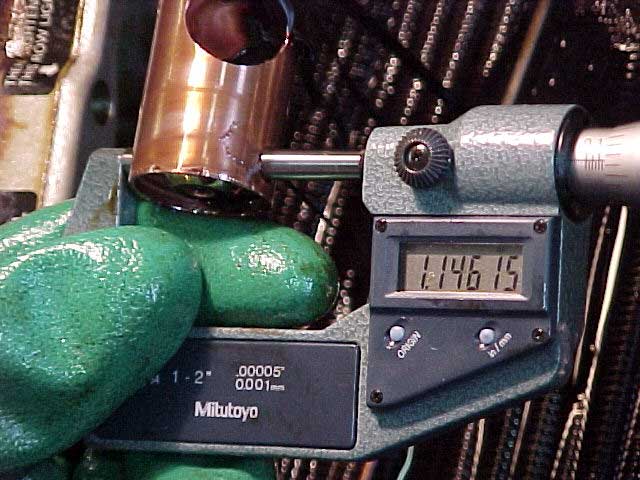

With the use of a bore-gage, we are able to confirm that a honed valve cylinder is straight and round.

The Process

Piston Valve Rebuilding (aka "valve-job")

Over time, it is not uncommon for piston valves to become worn to a point that the instrument no longer functions optimally. The rebuilding of piston valves is a precision process where the worn valve cylinders are restored straight and round. The pistons are repaired as needed and oversized through the electroplating application of copper and nickel. The plated materials are precision honed to the exact desired dimensions prescribed for their respective cylinders, ultimately returning it to a state of playability that can often exceed that of a new instrument. The tolerance of a properly rebuilt trumpet valve is approximately .0005" (one half of one thousandth of an inch). Larger piston tolerances are slightly more due to the added surface area. Once the valve and cylinders are fit correctly, they are hand lapped to the proper feel and function. Finally, the instrument is thoroughly cleaned and the ports are aligned with new materials. The springs are adjusted or replaced if found to be substandard.

External honing pistons, straight and round.

The Tooling

The honing process is performed with the use of precision machine tooling. We use Sunnen equipment exclusively for all of our precision honing. Most replacement components, in addition to all special fixtures and custom tooling, are made to order in house.

Other valve repair services

In addition to our valve rebuilding, we offer an array of additional valve repair services.

piston and cylinder straightening

replace broken and worn guide keys and spring towers

repair badly damaged or worn casing threads

repair or make replacement valve bearings and spindles

Fabrication of missing components, including stems, caps and buttons

Piston Valve Rebuild Pricing

Prices are based on the typical valve rebuild. Instruments requiring extensive additional cylinder corrections and extra copper build up may be charged extra based on time and materials. Any extra costs will be brought to the customer's attention before we proceed with the work, NO SURPRISES. These prices are approximates providing a guideline for those interested in our services. The turn around time depends on the shop's workload; we do our best to process valve rebuilds in three to eight weeks, but with valves requiring more work this can take a bit longer.

Please note: Very old, worn and damaged valves often need secondary copper plating and honing.

Trumpets and cornets: 500.00 for set of three (Piccolo additional 4th valve- add 185.00)

Flugelhorns: 525.00 for set of three (additional 4th valve- add 185.00)

Secondary plating for trumpets, cornets and flugelhorns - add: 215.00 per set of three. Large brass - note: in most instances, valve assemblies must be unsoldered from the instrument to allow for the cylinder honing process. We can perform the task but recommend that this be done by your trusted local repair shop. This allows for considerable savings in shipping costs. If you would like, we can work with your repair team directly.Valve trombones, conventional (standard) baritone and euphonium - 585.00 for set of three (additional valve - add 190.00 ea)

Compensating baritone and euphonium: 625.00 for set of three (additional valve- add 215.00 each).

Secondary plating - add: 240.00 per set of three (additional valves- add 80.00 each).

Tubas and sousaphones:

Tubas- conventional (standard): 930.00 per set of three (additional valves- add 310.00 each).

Tubas- Compensating: 980.00 per set of three (additional valves- add 310.00 each).

Secondary plating - add: 240.00 per set of three (additional valves- add 80.00 each).

How To Get The Ball Rolling?

First, give us a call at 206-241-5767 or email the shop at dcoberloh@oberloh.com, we are easy to reach and will answer all your questions, even if you're not quite ready to pull the trigger. We can discuss your project and go over the details, so you are comfortable with the process and all that is involved. We will also advise you on proper packing and shipping. Please understand that some projects do require a deposit in advance before work is started. We accept all major credit cards.

Again,We provide support services for commercial repair shops. Please call or email for details.

SERVICES | SALES | THE STAFF | GALLERY | EMAIL

Copyright 1997-2021 Oberloh Woodwind and Brass Works