Stage #2

Dent Work

Bells

Now we take on the part that calls for SKILL.

The job of overhauling large brass requires a great deal

of tooling. You can't get away with the bare minimum if you are going to

do higher quality work.

When it comes to tools my Dad would say, "Buy good tools

and you will only have to buy them once," provided you take care of them.

He was a smart man and knew what he was talking about. My tools paid for

themselves long ago and are still providing me and my staff with a livelihood.

The bells that have wreaths typically suffer the ugliest damage of them all and are the costliest in time and material to restore properly. We start out using a tool that is sort of like the old rolling pin my grandma used for pie dough. But in this case it is made of steel, the handle goes in a vice and the dough is the bell. The creases are softened as the bell is pressed against the roller and passed back and forth.

This process is also performed on the outside of the flair.

Eventually the flair is evened out and looks more like it should, though it is still very distorted.

At this stage the wreath has to come off. Sorry, but that's the way it has to be. We need to reach all the dents and the wreath will be in the way.

This is a hook nosed hand burnisher. We will use it to pull up the inside edge of the wreath that was originally spun around and over the rim of the bell. Caution: Wear protective gloves or you will shred your fingers.

The tip of the burnisher is gently pried under the edge and it is bit by bit pulled up as the tool is pushed around the inside radius of the bell rim.

The edge of the wreath is slowly and gently coaxed upward

90 degrees all the way around. Once the outside edge can be pulled

loose the inside edge of the wreath will be unsoldered if necessary.

The wreath will be free of the bell and out of the way to allow us to proceed

with the pressing of the bell.

Once the wreath is out of the way, all remaining solder

is removed and the bell is pressed out smooth. The only way to do it in

an affordable manner is with the use of a dent machine.

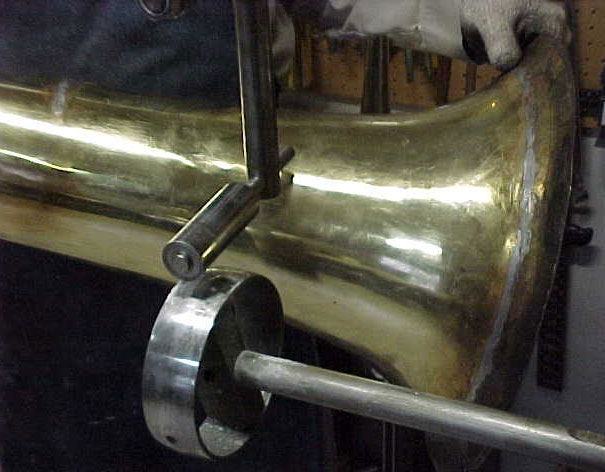

This is the Z-60 made by the Ferree's Tool Co. of Battle Creek, Michigan.

If you want good quality results, there are plenty of additional tools that come with the unit and even more available separately. The above image is a set up with one of the many rollers you can get and a fixed type shoe.

The set-up above shows the power disc roller configuration. The power disc is the lower shoe which is a spinning dome that greatly eliminates most friction and reduces the amount of marring that is common with the stationary shoe configuration. This set-up also utilizes what is known as a drop mandrel, allowing us to work on the larger bells such as tubas, french horns and some bass trombones. The tools are lubricated and the sheet brass is guided through where eventually the creases are pressed smooth.

There are a number of set ups used to remove dents and

reround the tapered cylinders.

Firm yet even pressure is applied as the bell is steadily

passed through.

A good deal of time is needed to achieve the desired results.

It is a simple enough idea but do not be fooled, it can make dents much

easier than it can remove them. Learning to operate this tool takes time and patience.

Eventually those ugly creases are removed and the bell

is nice and smooth.

We like to lightly polish the surface between stages as

it helps focus on any distortion that may have been overlooked. During

this stage any cracks that are discovered are ground out and silver brazed

and then finally dressed so they will not be noticeable.

Now that the bells are free of dents they will be sanded

by hand then polished thoroughly. Once polished the wreaths will be installed.

HOME | SALES | GALLERY | EMAIL