(Straighten, Parallel and Level)

Part 4

Inside Slide

Sighting down the outside length of the inside tubes aids

at detecting imperfections such as dents, creases or warping. Inside tube

damage is not as common as that to the outside tubing but it is very important

that it be addressed. No matter how straight the outside assembly

is, the slide, as a whole, will not work at its best if one of the inside

tubes remains distorted.

On this instrument, one of the inside tubes was damaged

to such an extent that it required unsoldering from the cork-barrel in

order for the proper repairs to be made.

The inside tubes can at times be very stubborn.

Mandrels, burnishers, mallets and so on are used but the skill of the repair

technician is what really gets the job done.

Now that the inside tube is straight, the cork-barrel

is mounted onto its respective tube. It is important that the tube be centered

or the screw lock will catch on the end of the outside tube in addition

to causing problems with the inside tube's proper alignment.

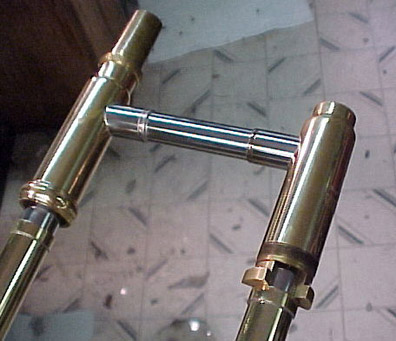

For this process we use a set of three spacers that center the cork-barrel on the inside tube. Using the outside tube to evenly wedge in the brass spacers, the cork-barrel is made to center perfectly on the inside slide tube.

Cork Barrel Spacers, Ferree's Tools Part No. G35

Once the inside assembly is fitted together, and appropriate

adjustments made, it is carefully soldered together. Then it is ready to

be polished, cleaned and prepaired for spot lacquering.

Part 1 - Evaluation and Preparation for Repair

Part 2 - Cleaning and Dent Removal

Part 3 - Assembly and Soldering